The construction of the new ‘Water World’ includes indoor and outdoor pools, rides, and facilities, new access provisions and sewerage works. Sustainability highlights include the use of full 4D Building Information Modelling integrated with the programme to improve efficiency and reduce waste from abortive works and the use of plant sensors.

Photogrammetry Orthogonal Imaging –

Utilising an orthogonal site image developed by aerial photogrammetry survey by drone to review layouts of underground utilities against existing site context. This improved productivity and minimised waste from re-work due to clashes.

Plant Management –

The sensor captures vibration data to identify the status of operation. Based on the frequency curve for vibration, we are able to understand the operational behaviour. This can be used to diagnose potential issues and conduct preventive maintenance as well as increase plant utilisation and energy efficiency.

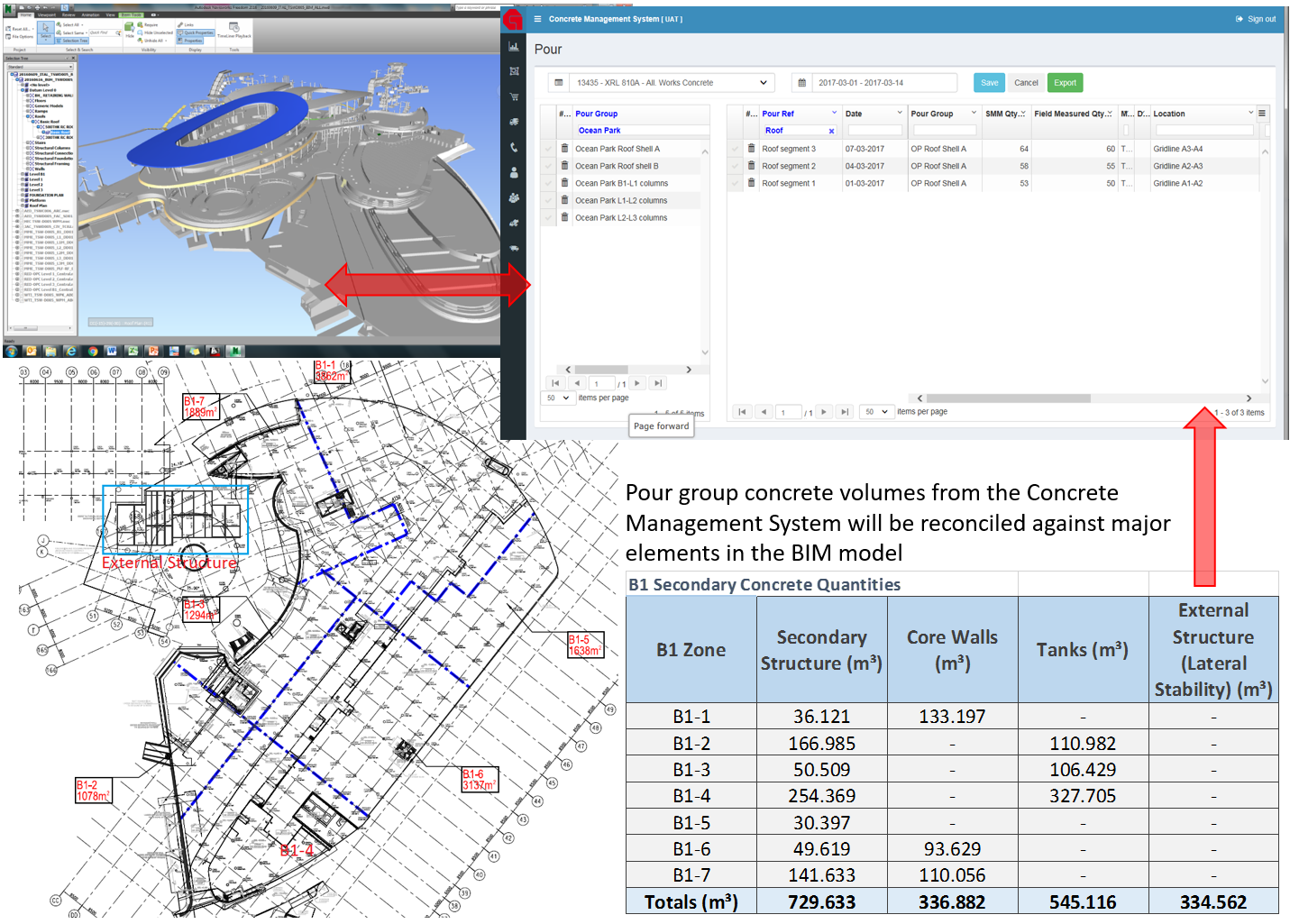

Concrete Volume Reconciliation –

The project team extracts concrete volumes from the BIM model to ensure accuracy of concrete orders for the complex, irregular shapes on the project. The in-house, paperless Concrete Management System is then used for ordering and finally the ordered and BIM concrete volumes are reconciled. This process reduces potential wastage from over-ordering.